Select the Right Pressure Gauge for Your Application

You need accurate and dependable pressure gauges to keep your operation running efficiently and safely while ensuring industry and regulatory standards. However, finding the best solution to meet your specifications can be completely overwhelming. We created this tool to help you select the right pressure gauge for your needs.

Get StartedChoose application where the pressure gauge will be used.

Your choice will depend on the industry application. For instance, a gauge used in a high-purity environment has different requirements than one used in hydrogen systems.

Verify approval requirements. Select all that apply.

Some applications require approvals from nationally or internationally recognized agencies.

Confirm pressure type.

There are two gauge styles: one for measuring differential pressure and one for measuring gauge pressure.

Determine gauge size. Select all that apply.

The dial or case size can vary based on the application and dimensions of where the gauge will be used.

Select case style.

The style will depend on your application and safety requirements.

Choose case material.

The case material you select must align with specific industry specifications and/or requirements.

Identify connection location.

Where will the pressure gauge connect to the process?

Select the pressure range.

The range must align with the operating pressures of your process and follow ASME B40.100 best practices.

Verify the accuracy requirements.

The accuracy should align with your application requirements and ASME B40.100 or EN837-1 best practices.

Select your gauge's wetted part material.

The wetted materials need to be compatible with the process media you are measuring. If you are unsure, refer to the Material Selection & Corrosion Guide Tool.

Review your selections

Please take a moment to confirm your responses. To make changes, click on the applicable step and update your selections.

**If you make any changes, all subsequent steps will cleared, and you will need to make your selections again.

Review your selections

Please take a moment to confirm your responses. To make changes, click on the applicable step and update your selections. If you make any changes, all subsequent steps will cleared, and you will need to make your selections again.

Fill out the form to see which pressure gauges we recommend.

Here are your recommended pressure gauges.

If there are multiple gauges to choose from, you can select up to five to compare specifications.

Need Assistance Start Over

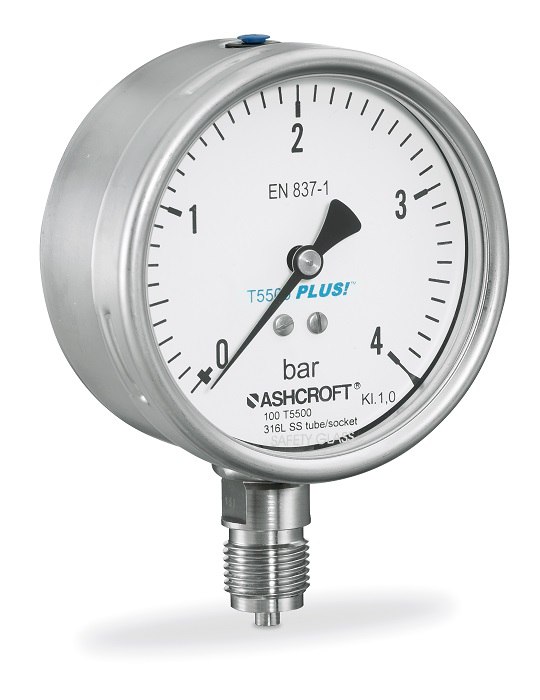

- Wide selection of Bourdon tube materials, pressure connections and pressure ranges

- Solid-front case design for safety

- Teflon®-coated, 400 stainless steel movement

- PLUS!™ Performance (option)

- NSF-61 Compliant (316L Stainless steel wetted parts)

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- True Zero™ reduces reading errors by using a “zero box” instead of conventional dial pins (posts); this ensures product safety, integrity and system control

- PLUS!™ Performance (option)

- Field Fillable

- NSF-61 Compliant (316L Stainless steel wetted parts)

- PowerFlex™ movement providing superior shock, vibration and pulsation performance available on most sizes

- All welded Stainless steel construction

- True Zero™reduces reading errors by using a “zero box” instead of conventional dial pins (posts); this ensures product safety, integrity and system control

- PLUS!™ Performance or FlutterGuard™(optional)

- Extensive connection sizes/locations to address a wide range of installations

Liquid fillable - NSF-61 Compliant

- Meeting EN837-1 and ASME B40.100 specifications allows for international use

- R110 and NGV 3.1 approvals

- FlutterGuard™ standard on dry gauges

- Extensive offering of process connection locations and ranges

- Economical solution when all stainless gauges are required

- Designed to meet MSL Helium leak test of 1 x 10-6 scc/s

- Optional solid front design (XS3)

- R110 and NGV 3.1 approvals

- FlutterGuard™ standard on dry gauges

- Extensive offering of process connection locations and ranges

- Economical solution when all stainless gauges are required

- Designed to meet MSL Helium leak test of 1 x 10-6 scc/s

- Meeting EN837-1 and ASME B40.100 specifications allows for international use

- Solid-front case design for safety

- PLUS!™ Performance (option)

- Large 5 digit LCD display

- Simple Push-button menu navigation

- 9 engineering units: 1 field-programmable

- Min. / Max. function records low and high pressure events

- 20 segment Bar graph display

- Wide variety of pressure connection thread options

- Protective boot (optional)

- Customizable keypad (optional)

- All-stainless steel movement

- Socket welded to case

- PLUS!™ Performance (option)

- Clean or steam in place (CIP/SIP)

- Autoclave or sterilize with 3½˝ dial with polysulfone window option

- Easy Zero™ provides external adjustability of instrument span (3½˝ dial)

- 12-15 RA (microinches) electropolished diaphragm surface

- Material certificates and certificate of conformance supplied as standard to EN 10204:2004 3.1

- PLUS!™ Performance option

- 316L stainless steel and Hastelloy C276 diaphragm and housing available

- Temperature compensated from 0 to 150°F (-18-60° C)

- Three accuracy levels 0.05%, 0.1% and 0.25% terminal point method

- 12 engineering units

- 7 different languages

- Field calibration capability

- Battery powered

- Includes stainless steel cover and padded carry pouch

- Stainless steel case 2″ for limited space up to 6″

- High static pressure capability (up to 6,000 psi)

- Reed switches for direct system control (optional)

- Superior magnets for smoother pointer motion

- All-stainless steel movement

- Socket welded to case

- High over pressure up to 400% of range option XRA (see datasheet for specifications)

- Low ambient temperature option for arctic conditions from -94°F (-70°C)

- PLUS!™ Performance (option)

- Wide selection of Bourdon tube materials, pressure connections and pressure ranges

- Solid-front case design for safety

- Teflon®-coated, 400 stainless steel movement

- PLUS!™ Performance (option)

- Inches of water ranges

- Bronze, 316 stainless steel or monel wetted parts

- Available with diaphragm seals

- Visual Pressure Indicator

- Full 5 digital LCD display

- Up to 10 preprogrammed engineering units

- Password protection

- Damping

- Display Update rate

- Min/Max

- Auto-off timers

- Field Recalibration possible

- 4-20mA Loop Powered

- 4-20mA Analog Output (optional)

- SPDT switch output (optional)

- MicroSpan™ adjustment eases span calibration

- Mirror-band dial and knife-edge pointer eliminates paralax error

- Solid-front case design for safety

- Teflon®-coated, 400 stainless steel movement

- Case designed for easy panel mounting

- Front hinged ring for panel mounting

- Wide selection of Bourdon tube materials, pressure connections and pressure ranges

- Solid-front case design for safety

- Teflon®-coated, 400 stainless steel movement

- PLUS!™ Performance (option)

- Isolates and protects instrument assembly from pressure surges beyond the full scale of the measurement instrument

- Prevents damage, loss of accuracy and / or rupture of sensing elements

- 316Ti stainless steel construction

- Automatically resets after 25% drop in pressure from set point

- Available set point from 6 psi to 8,700 psi

- Built-in pressure snubbing design

- Supplies with wetted parts according to NACE MR0175/MR0103

- Material Traceability Reports available per EN 10204 3.1

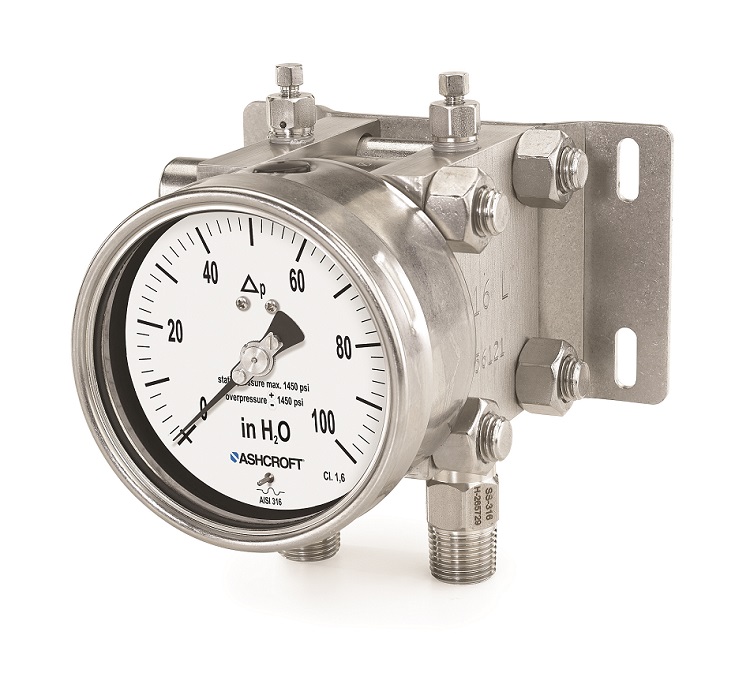

- Robust housing

- Selection of wetted materials

- Extremely High static pressure limits

- External zero adjustment

- Flow measurement dial (optional)

- Electric contacts (optional) for process monitoring and control

- NACE compliant (optional)

- Ability to attach to diaphragm seals starting at 60 IWD (3 PSID)

- Robust housing

- Selection of wetted materials

- Extremely High static pressure limits

- External zero adjustment

- Flow measurement dial (optional)

- Electric contacts (optional) for process monitoring and control

- NACE compliant (optional)

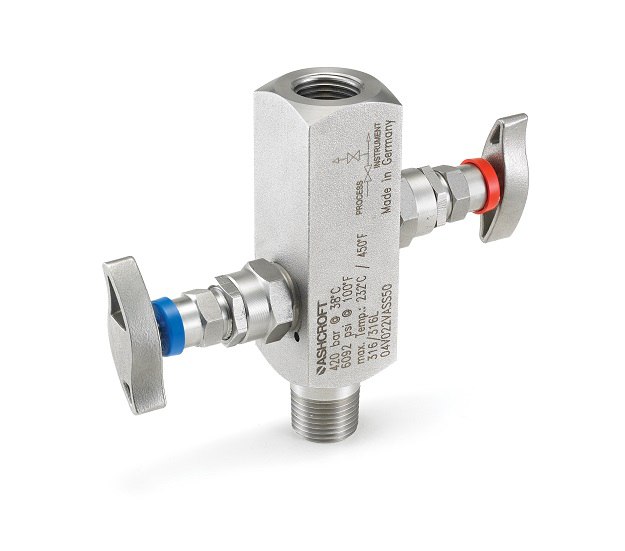

- Isolates process from instrument assembly

- 316L stainless steel construction

- Externally adjustable gland

- Reinforced gland body protection

- Blowout protection

- Non-rotating needle provides bubble tight shut-off

- Available with vent port/plug (Style B)

- Material Traceability Reports available per EN 10204 3.1

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm welded (metallic) or bonded (elastomer) to top housing

- Flushing port (type 201) provides easy cleaning / flushing for process media prone to clogging

- NSF-61 Compliant

- Effectively protects instruments from elevated temperatures

- Siphon and sensing instrument mount directly to the process

- 316L stainless steel, compatible with many process media

- Used with gauges, switches, transducers and diaphragm seals

- Easily removable polycarbonate window for small zero adjustments

- FlutterGuard™ option to reduce movement wear and eliminate pointer flutter

- Case is suitable for intermittent or continuous services on natural gas

- Isolates process from instrument assembly

- 316L stainless steel construction

- Support mounting brackets available

- Color-coded dust caps prevent dust ingress and identify handle functions

- PTFE packing (other materials available upon request)

- Stem with cold rolled surface, back seat and non-rotating needle tip

- Supplied with wetted parts according to NACE MR0175/MR0103

- Material Traceability Report available per EN 10204 3.1

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm welded (metallic) or bonded (elastomer) to top housing

- Flush port (type 203) provides easy cleaning / flushing due to process media prone to clogging

- Isolates and bleeds the process media from instrument assembly

- 316L stainless steel construction

- Externally adjustable gland

- Reinforced gland body protection

- Blowout protection

- Non-rotating provides bubble tight shut-off

- Material Traceability Reports available per EN 10204 3.1

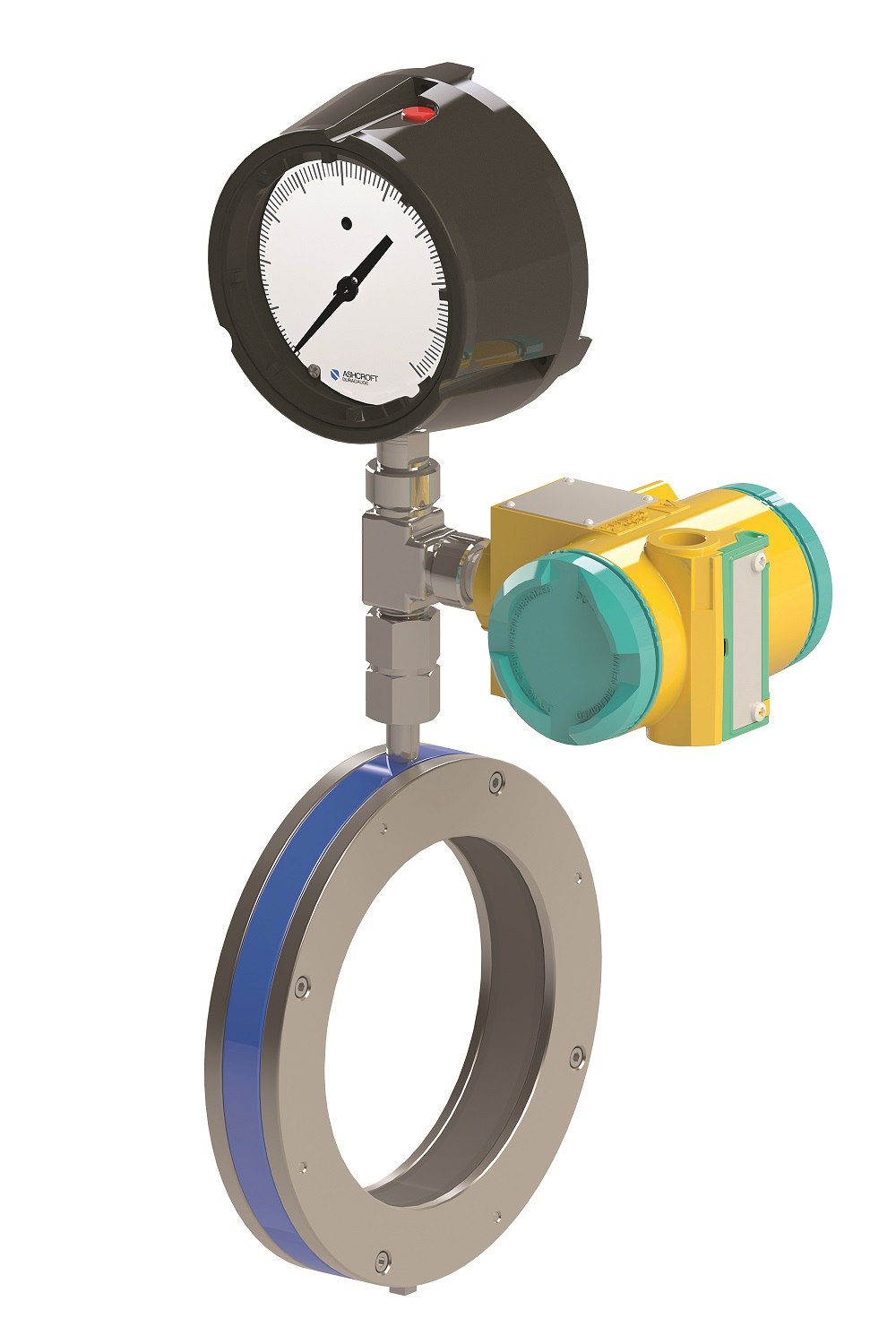

- 360° sensing flexible inner-liner; no process deadleg

- Safe Quick Release™ (optional) enables instrument removal without loss of fill or process shutdown

- Needle valve (optional) dampens pulsation effects

- Retrofit end plates (optional) allows easy replacement of other manufacturer models

- NSF-61 Compliant

- Complies with ASME B40.100

- Solid-front case design for safety

- Socket-to-case weld for superior leak integrity

- 316L stainless steel case, ring and back cover

- 316L stainless steel or Monel wetted parts

- Full pressure relief back cover

- PLUS!™ Performance (OPT.)

- High over pressure up to 417% of range option XRA (see datasheet for specifications)

- Isolates and bleeds the process medium from the instrument assembly

- 316L stainless steel construction

- Support mounting brackets available

- PTFE packing (other materials available upon request)

- L-shape, Y-Sshape or inline body style options available

- Color-coded dust caps prevent dust ingress and identify handle functions

- Stem with cold rolled surface, back seat and non-rotating needle tip

- Supplied with wetted parts according to NACE MR0175/MR0103

- Material Traceability Reports available per EN 10204 3.1

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm threaded to top housing

- Flushing port (type 101) provides easy cleaning/flushing for process media prone to clogging

- Compact Design

- All Stainless Steel sensor element

- Polysilicon thin film sensor

- Highly configurable, wide selection of pressure & electrical connectors, outputs, and pressure ranges

- Stainless steel housing, sensor and pressure connections.

- +/-0.25%, +/- 0.50% or +/-1.0% of span accuracy available

- Diaphragm available in 17-4 PH, 316L SS and A286 SS

- Standard ranges from vacuum to 20,000 psi and 0 to 500 psia (custom ranges available)

- External magnetic offset and span adjustment.

- Wide assortment of analog outputs, pressure and electrical connections.

- Custom cable lengths.

- Customizable configurations

- UL and CE approved

- SIL 3 Capable

- RoHS compliant

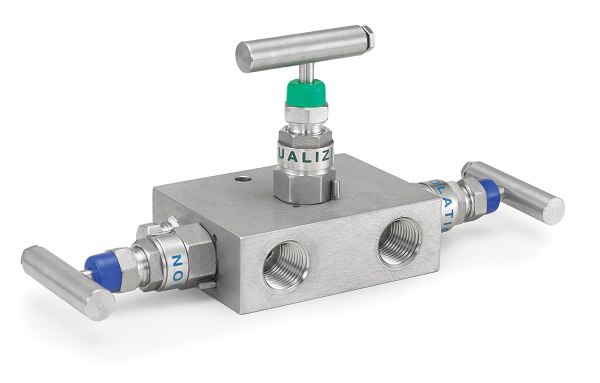

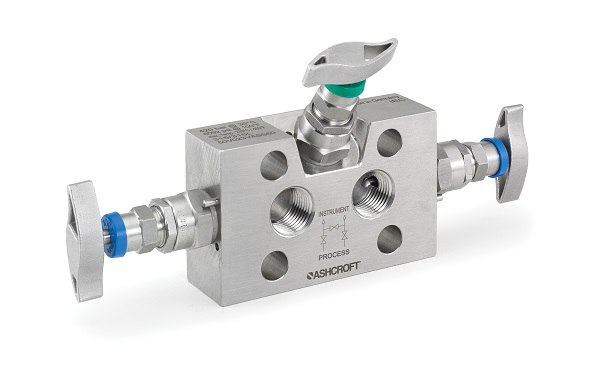

- Isolates each port and equalizes pressure for instrument maintenance

- 316L stainless steel construction

- Support mounting brackets available

- PTFE Packing

- Color-coded dust caps prevent ingress of contaminants and identify handle functions

- Material traceability reports available per EN 10204 3.1

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- FlutterGuard™ (option on dry gauges) reduces movement wear and eliminates pointer flutter; extends product life and allows easy gauge readability

- True Zero™ reduces reading errors by using a “zero zone” instead of conventional dial pins (posts); this ensures product safety, integrity and system control

- Available dry, liquid-fill or field-fillable versions

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm threaded to top housing

- Flush port (model 103) provides easy cleaning / flushing due to process media prone to clogging

- Pressure ranges from vacuum to 20,000 psi

- +/- 0.25% of span static accuracy (BFSL) at reference temperature

- All stainless steel wetted materials

- Highly configurable; wide selection of pressure connections and electrical terminations

- Voltage and 4-20mA output options

- High EMI/RFI immunity rating

- UL/cUL and CE approved

- RoHS compliant

- NSF-61 Compliant

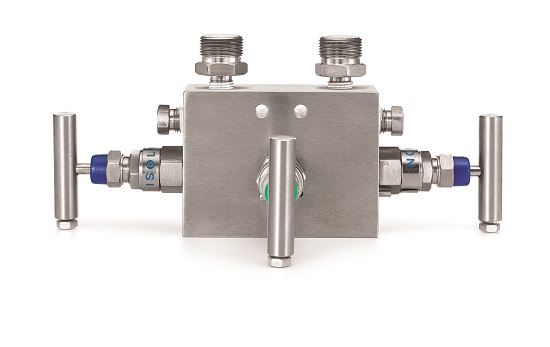

- Isolates each port and equalizes pressure for instrument maintenance

- 316L stainless steel construction

- Support mounting brackets available

- PTFE packing (other materials available upon request)

- Color-coded dust caps prevent dust ingress and identify handle functions

- Stem with cold rolled surface, back seat and non-rotating needle tip

- Supplied with wetted parts according to NACE MR0175/MR0103

- Material Traceability Reports available per EN 10204 3.1

- Isolates each port and equalizes pressure for instrument maintenance

- 316L Stainless steel construction

- Support mounting brackets available

- PTFE packing

- Color-coded dust caps prevent ingress of contaminants and identify handle functions

- Material traceability reports available per EN 10204 3.1

- Remote or direct mount available

- 360° sensing flexible inner-liner; no process deadleg

- Safe Quick Release™ (optional) enables instrument removal without loss of fill or process shutdown

- Needle valve (optional) dampens pulsation effects

- Retrofit end plates (optional) allows easy replacement of other manufacturer models

- NSF-61 Compliant

- Uses Ashcroft’s proven thin film technology

- +/-0.25%, +/- 0.50% or +/-1.0% of span accuracy available

- Pressure ranges from vacuum to 10,000 psi and 0 to 7,500 psia (custom ranges available)

- Rugged 304 stainless steel Housing

- Highly configurable; wide selection of pressure connections and electrical terminations

- Multiple voltage or 4-20 mA outputs available

- ATEX and UL/cUL explosion-proof and flame-proof approvals

- FM and CSA intrinsically safe/non-incendive approved (standard on 4-20mA output only)

- CE approved

- RoHS compliant

- Uses Ashcroft’s proven thin film technology

- +/-0.25%, +/- 0.50% or +/-1.0% of span accuracy available

- Standard ranges from vacuum to 20,000 psi and 0 to 500 psia (custom ranges available)

- Rugged 316 stainless steel Housing

- Diaphragm available in 17-4 PH, 316L stainless steel or A286

- FM, CSA, ATEX and IECEx intrinsically safe approvals

- FM and CSA non-incendive approvals

- 4-20mA or multiple Voltage outputs available

- External magnetic offset and span adjustment

- CE approved

- SIL 3 Capable

- RoHS compliant

- FM, CSA ATEX and IECEx flameproof approvals

- FM and CSA non-incendive approvals

- Uses Ashcroft’s proven CVD thin film technology

- +/-0.25%, +/- 0.50% or +/-1.0% of span accuracy available

- Standard ranges from vacuum to 20,000 psi and 0 to 500 psia (custom ranges available)

- Rugged 316 stainless steel Housing

- Diaphragm available in 17-4 PH, 316L stainless steel or A286

- 4-20mA or multiple Voltage outputs available

- External magnetic offset and span adjustment

- CE approved

- SIL 3 Capable

- RoHS compliant

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- True Zero™ reduces reading errors by using a “zero box” instead of conventional dial pins (posts);this ensures product safety, integrity and system control

- FlutterGuard™ (option) reduces movement wear and eliminates pointer flutter; extends product life and allows easy gauge readability

- 1/4 turn polycarbonate window provides better dial visibility and easy removal

- Isolates and bleeds the process medium for each port and equalizes pressure

- 316L stainless steel construction

- Support mounting brackets available

- PTFE packing

- Color-coded dust caps prevent ingress of contaminants and identify handle functions

- Material Traceability Reports available

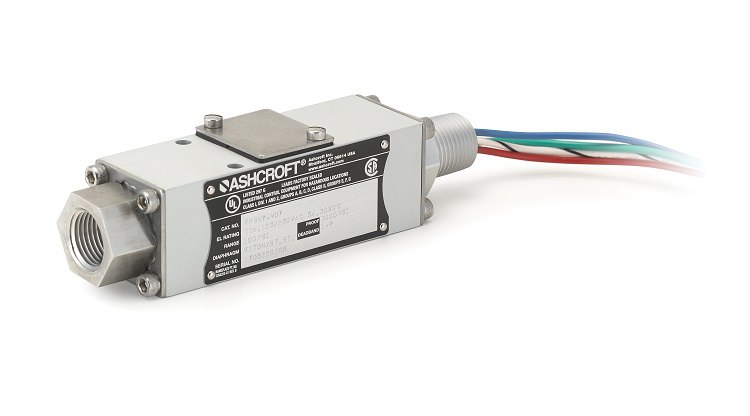

- 316L stainless steel enclosure provides uncompromising protection

- Pressure ranges from vacuum to 15,000 psi (1000 Bar)

- Wide operating temperature -40°F to 212°F (-40°C to 100°C)

- Factory set or field adjustable setpoint with Fixed deadband

- Expanded selection of pressure and electrical connections

- SIL 3 Capable

- UL, CSA, CE, CRN and 3A approved

- RoHS Compliant

- NSF-61 Compliant

- All-welded, compact size and lightweight

- Continuous duty

- All-welded construction; prevents inadvertent disassembly

- All-stainless steel construction; other materials available

- Flush port (type 511) provides easy cleaning / flushing for process media prone to clogging

- TruAccuracyTM performance ensures the CXLdp meets its rated accuracy out of the box and is ready for installation with no additional calibration adjustments required.

- LED indicator for trouble-shooting, correct wiring or locating product

- Wide selection of differential pressure ranges

- Euro-style pluggable terminal block; reduces wiring errors and simplifies installation

- Field-selectable output (voltage version)

- DIN Rail Mount is standard

- Compact design

- Excellent overpressure protection

- Superior long-term stability

- 3-Year Warranty

- CE Mark is standard

- Isolates and bleeds the process for each port as well as equalizing pressure for instrument maintenance

- 316L stainless steel construction

- Support mounting brackets available

- PTFE packing (other materials available upon request)

- Color-coded dust caps prevent dust ingress and identify handle functions

- Stem with cold rolled surface, back seat and non-rotating needle tip

- Supplied with wetted parts according to NACE MR0175/MR0103

- Material Traceability Reports available per EN 10204 3.1

- Compact, 316L stainless steel housing and wetted materials

- Explosion-proof housing provides uncompromising protection

- Pressure ranges from -15 psi (vacuum) to 15,000 psi

- Wide operating temperature -40°F to 192°F (-40° to 89°C)

- Factory set or field adjustable setpoint, Fixed deadband

- Expanded selection of pressure and electrical connections

- SIL3 Capable

- FM,UL, CSA, ATEX and IECEx hazardous approvals

- CE, CRN and 3A approved

- RoHS compliant

- Ultra-compact case design

- Electropolished 316L AOD/VAR stainless steel wetted parts

- 100% Helium leak tested

- Class 100 cleanroom packed and double bagged

- Compact and lightweight design

- All-welded construction

- Choice of diaphragm and lower housing materials

- Pressure rated up to 2,500 psi at 100°F

- Volumetric displacement allows attachment to: 3 1/2″ gauges (60 to 1,000 psi)

transducers and switches

- TruAccuracy™ performance ensures the DXLdp meets its rated accuracy out of the box and is ready for installation with no additional calibration adjustments required.

- LED range status indicators for instant troubleshooting information

- Wide selection of differential pressure ranges down to +/- 0.05 in. H2O

- The exclusive patented Ashcroft SpoolCal® actuator provides in-place system calibration, thus adding great value when validating a process on-line or calibrating the unit

- Standard DIN Rail mount reduces installation costs

- Excellent over-pressure protection

- Custom pressure range calibrations are readily available

- Superior long-term stability

- 3-Year Warranty

- CE Mark standard

- Front access test jacks provide on-line signal reference without disconnecting power supply wiring

- Isolates and bleeds the process for each port and equalizes pressure

- 316L Stainless steel construction

- Support mounting brackets available

- PTFE packing

- Color-coded dust caps prevent ingress of contaminants and identify handle functions

- Material Traceability Reports available

- Remote or direct mount available

- Special designs for UL fuel and steam limit control

- Adjustable setpoints from 15%-100% of range

- Fixed or limited adjustable deadband

- Wide selection of switch elements

- Stainless Steel, Buna, Viton, Teflon and Monel diaphragms available for compatibility

- Internal setpoint locking screw

- SIL3 Capable

- FM, UL, CE, CRN and 3A approved

- RoHS Compliant

- NSF-61 Compliant

- 360° sensing flexible inner-liner; no process deadleg

- Safe Quick Release™ (optional) enables instrument removal without loss of fill or process shutdown

- Needle valve (optional) dampens pulsation effects

- NSF-61 Compliant

- Predefined and custom cable lengths

- Small OD diameter (17mm) designed to fit narrow bore applications.

- Complete 316L stainless steel construction

- IP68 / NEMA 6P housing

- +/- 0.25% or +/- 0.50% of span accuracy

- Ranges from 1.5 psi to 300 psi (custom ranges available)

- Unit of Measure selection (psig, feet or meters of H2O)

- Excellent long-term stability

- 4-20 mA output (2-wire)

- Desicant filters, surge protection, termination box and cable hangers available

- CE Approved

- RoHS Compliant

- TruAccuracyTM performance ensures the GXLdp meets its rated accuracy out of the box and is ready for installation with no additional calibration adjustments required.

- Large LCD display with backlight

- Wide selection of differential pressure ranges down to +/- 0.05 IWC

- The exclusive patented Ashcroft Spool Cal actuator provides in-place system calibration, thus adding great value when validating a process on line or calibrating the unit

- Field selectable outputs

- Two programmable switch outputs, NPN or PNP

- Adjustable display response time

- Excellent over-pressure protection

- 3-Year Warranty

- CE Mark standard

- Lower and back mount connections

- 316L stainless steel wetted parts

- 100% Helium leak tested

- Polyethylene-sealed

- Class 100 cleanroom packaged and double bagged

- Lower and back mount connections

- 316L stainless steel wetted parts

- 100% Helium leak tested

- Class 100 cleanroom packaged and double bagged

- 316L Stainless steel wetted parts

- Helium leak tested to 1 x 10-8 scc/s

- Cleaned in class 10,000 clean room

- Polyethylene-sealed after nitrogen gas flushing

- Explosion-proof enclosure provides uncompromising protection

- Adjustable from 15%-100% of range

- Fixed or limited adjustable deadband

- Wide selection of switch elements

- Stainless Steel, Buna, Viton, Teflon and Monel diaphragms available for compatibility

- Ranges from vacuum to 3000 psi

- 316L Stainless Steel housing available

- External locking screw (ATEX / IECEx approval only)

- UL, CSA, ATEX and IECEx hazardous approvals

- CE, CRN and 3A approved

- SIL 3 Capable

- RoHS Compliant

- NSF-61 Compliant

- Flush design minimizes the use of expensive specialty wetted materials

- Flush-mounted diaphragm prevents clogging of process media

- Available with optional Flushing Ring

- Available with 1.5″ and 2.0″ Tri-Clamp® connection

- 3-A approved

- SIL 3 Capable

- Wide selection of electrical terminations

- Customized configurations

- External magnetic offset and span adjustment

- Isolates and bleeds the process from instrument assembly

- 316L stainless steel construction

- Available in process or instrument type

- OS & Y bolted bonnet isolation

- PTFE packing (other materials available upon request)

- Non-Rotating, blow-out proof needle

- Color coded dust caps prevent dust ingress and identifies handle function

- Supplied with wetted parts according to NACE MR0175/MR0103

- Material Traceability Reports available per EN 10204 3.1

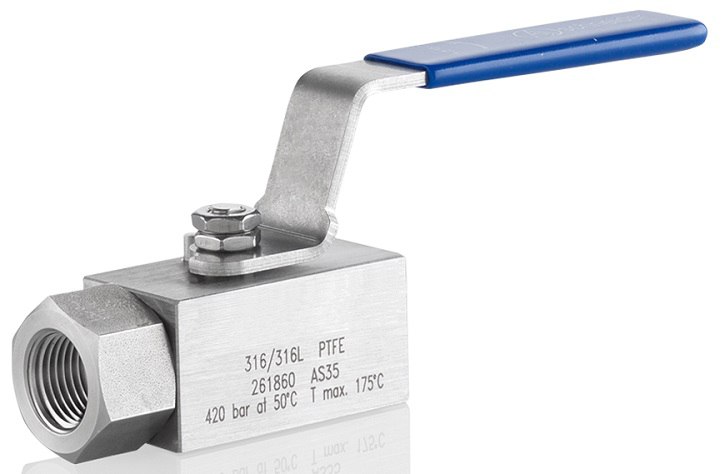

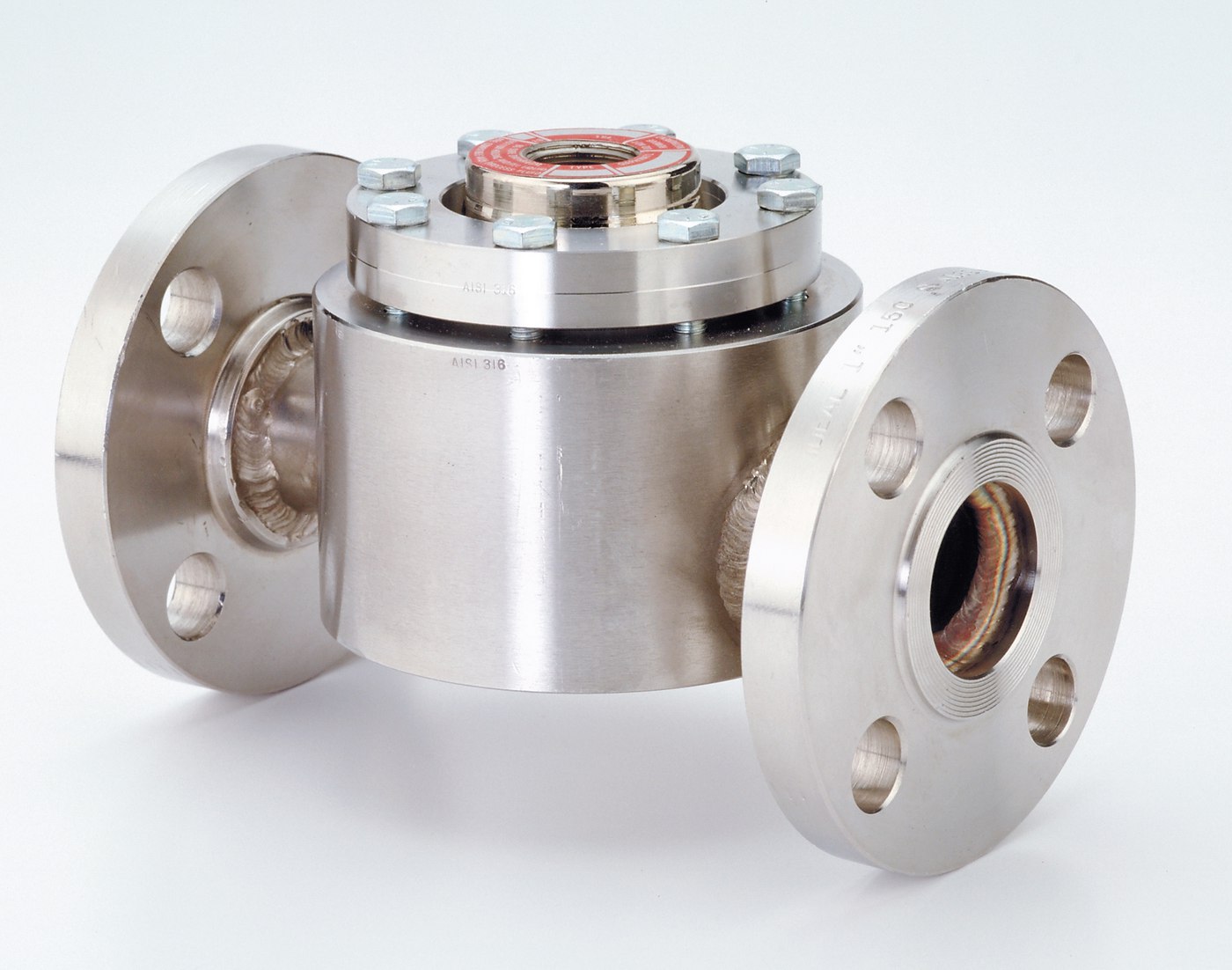

- 316L stainless steel construction

- 90° turn opens or closes valve quickly

- 10mm bore hole reduces clogging

- Floating ball design provides bi-directional isolation

- PTFE packing

- Supplied with wetted parts according to NACE MR0175/MR0103

- Adjustable setpoints from 15%-100% of range

- Fixed or limited adjustable deadband

- Wide selection of switch elements

- Stainless Steel, Buna, Viton, and Teflon diaphragms available for compatibility

- Internal set point lock screw

- SIL3 Capable

- FM, UL, CE, and CRN approved

- RoHS compliant

- Wide selection of diaphragm and lower housing materials

- Enlarged welded diaphragm; high displacement allows high sensitivity to pressure fluctuations

- Flush port (type 741) provides easy cleaning / flushing for process media prone to clogging

- Pressure ranges from vac to 20,000 psi

- +/-0.50% or +/- 1.00% of span accuracy

- Voltage and 4-20mA output options

- NEMA 4X

- All stainless steel wetted materials

- Highly configurable – broad selection of pressure ranges, output signals, pressure connections and electrical terminations

- FM Intrinsically safe or Non-incendive approval (optional)

- CRN approved

- PTFE/PFA Wetted Parts

- 100% Nitrogen leak tested

- Class 10,000 cleanroom packed and bagged

- Wide selection of Bourdon tube materials, pressure connections and pressure ranges

- Solid-front case design for safety

- Epoxy-coated system offers superior corrosion resistance

- PLUS!™ Performance (option)

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance cost

- True Zero reduces reading errors by using a “zero box” instead of conventional dial pins (posts); this ensures product safety, integrity and system control.

- PLUS!™ Performance (optional)

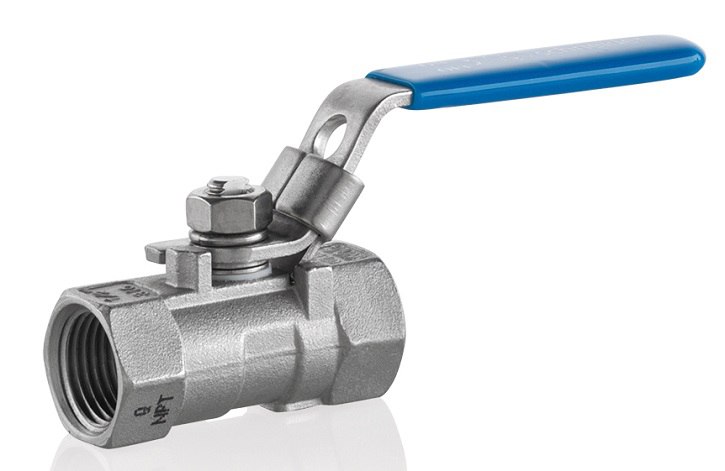

- Welded 3-hole front flange for easy installation

- 316L stainless steel construction

- 90° turn opens or closes valve quickly

- 9.2mm bore hole reduces clogging

- Floating ball design provides bi-directional isolation

- PTFE packing

- Anti-blowout stem design

- Supplied with wetted parts according to NACE MR0175/MR0103

- Adjustable setpoint from 15-100% of range

- Explosion-proof enclosure provides uncompromised protection

- Fixed or limited adjustable deadband

- Wide selection of switch element and wetted materials

- External locking screw (ATEX / IECEx approval only)

- Ranges from 30 in. H2O to 600 PSID

- UL, CSA, ATEX, IECEx hazardous approvals

- FM, CE and CRN approved

- SIL 3 capable

- RoHS Compliant

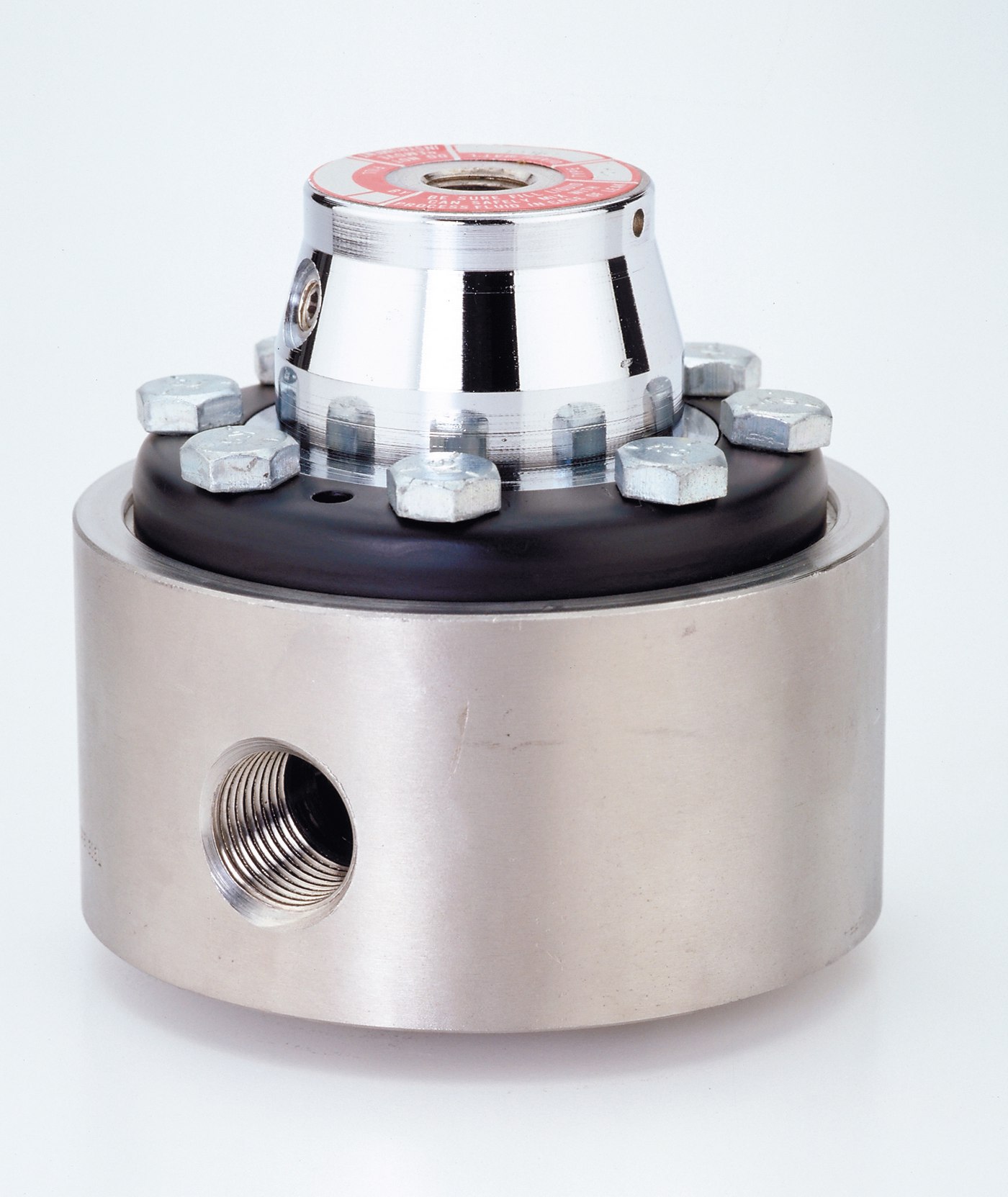

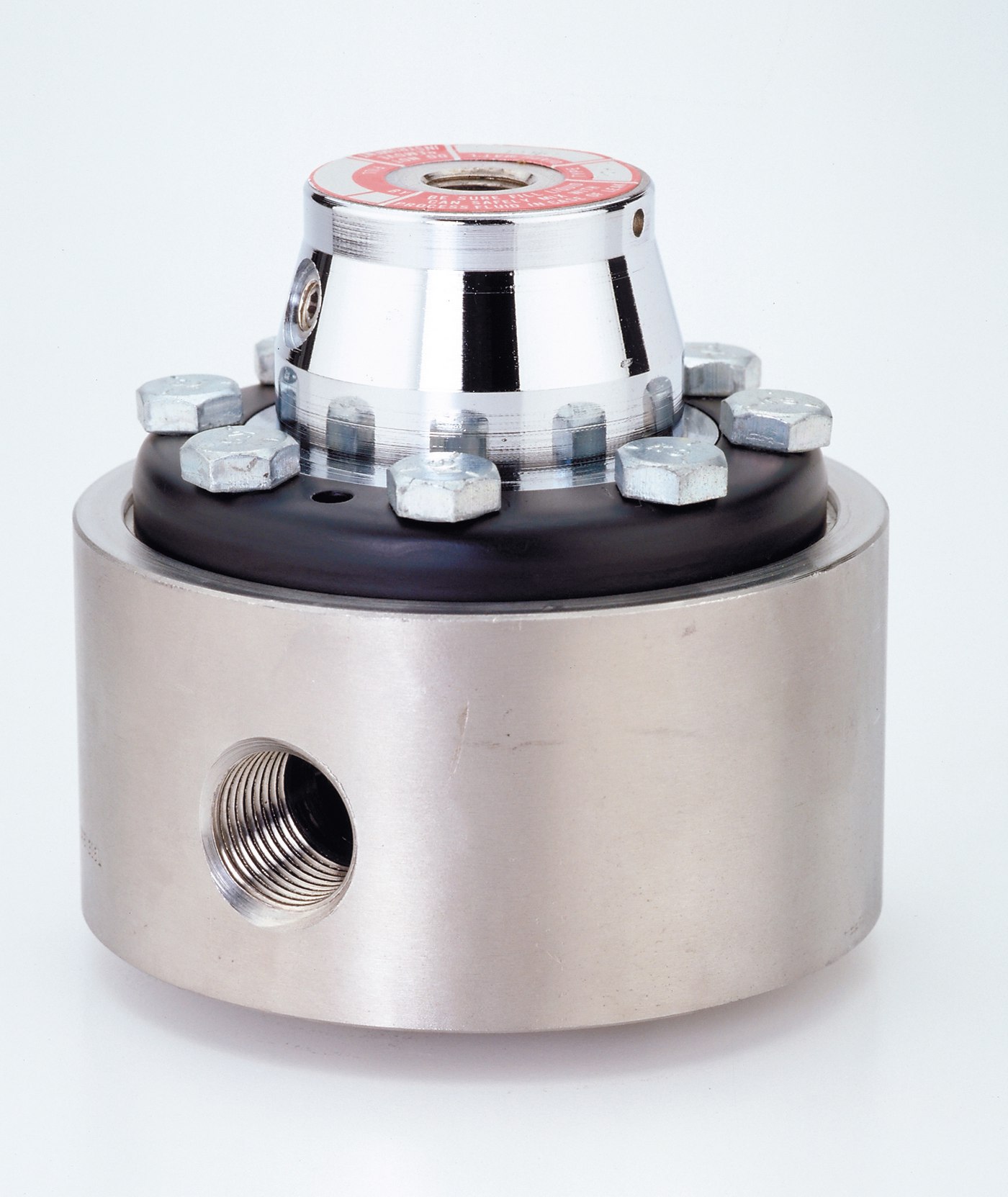

- Compact and lightweight design

- All-welded construction

- Flush diaphragm; eliminates clogging or process accumulation

- Volumetric displacement; For use with 3 1/2″ pressure gauges or smaller (60 to 3,000 psi)

- Pressure rated up to 3,000 psi

- Stainless Steel case

- High static pressure capability of 1,500 psi

- Superior magnets for smoother pointer motion

- Reed switches for direct system control (optional)

- Wide selection of switch elements

- Designed for easy field installation and wiring of microswitches

- Adjustable setpoints from 15%-100% of range

- Fixed or adjustable deadbands

- Single or dual independent setpoints

- UL, CSA, CE, CRN and 3A approved

- RoHS Compliant

- NSF-61 Compliant

- Compact and lightweight design

- Choice of diaphragm and lower housing materials

- All-welded construction

- Volumetric displacement allows attachment to:

3 1/2″ gauges (Vac to 1,000 psi)

4 1/2″ gauges (30 to 1,000 psi)

Transducers and Switches - Rated up to 1,000 psi

- Effectively protects instruments from elevated temperatures

- Siphon and sensing instrument mount directly to the process

- Built-in dampening mechanism combats process pulsation

- Compatible with many process media

- Use with gauges, switches, transducers and diaphragm seals

- Designed for easy field installation and wiring of microswitches

- Ranges from 30 in. H2O to 400 PSID

- Wide selection of switch elements

- Stainless steel, Buna, Viton, Teflon and Monel diaphragms available for compatibility

- Adjustable setpoints from 15%-100% of range

- Fixed or adjustable deadbands

- FM, UL, CSA and CE approved

- RoHS Compliant

- Wide selection of Bourdon tube materials, pressure connections and pressure ranges

- Solid-front case design for safety

- PLUS!™ Performance (option)

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm (elastomer) clamped between top and bottom housings

- Flushing port (type 301) provides easy cleaning / flushing for process media prone to clogging

- Choice of types; material and capacity

- Dissipates elevated live steam temperature

- Reduces process temperature to protect attached instrument

- Compact, 316L stainless steel housing provides uncompromising protection.

- Stainless steel, Buna, Viton, Teflon and Monel diaphragms available for compatibility

- Wide selection of switch elements

- Factory set or field adjustable setpoint

- UL, CSA, CE, CRN and 3A approved

- RoHS Compliant

- NSF-61 Compliant

- Select diaphragm and lower housing materials

- All-welded construction

- Carbon steel rings (standard); 300 stainless steel rings (optional)

- Pressure rated up to 4,400 psi; optional high-pressure rings to 9,000 psi (type 401: 5,000 psi )

- Flush port (type 401) provides easy cleaning / flushing for process media prone to clogging

- Cost effective

- Designed for high vibration resistance

- Custom dials available

- Accessory kits available for easy retrofit mounting

- True Zero™ indication, a unique safety feature

- Ventable fill plug

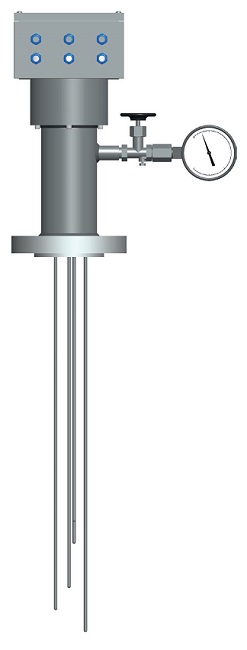

- All-welded stainless steel construction

- 5 foot length (standard); alternate lengths in 5 foot increments

- Available capillary lengths: 1 foot to 100 feet

- Designed for easy field installation and wiring of microswitches

- Ranges from 30 in. H2O to 400 psid

- Wide selection of switch elements

- Stainless steel, Buna, Viton, Teflon and Monel diaphragms available for compatibility

- Adjustable setpoints from 15%-100% of range

- Fixed or adjustable deadbands

- Wide selection of diaphragm and lower housing materials

- Enlarged welded diaphragm; high displacement allows high sensitivity to pressure fluctuations

- Flushing port (type 703) provides easy cleaning / flushing due to process media prone to clogging

- All metal construction

- Select porosity settings based on process media

- Filter disk; less tendency to clog than orifice-type devices

- NEMA 7 & 9 Explosion Proof Enclosure

- Dual chamber design allows for field calibration to be performed safely, even with power connected

- Ranges from vacuum to 3000 psi

- Wide selection of switch elements

- Stainless Steel, Buna, Viton, Teflon and Monel diaphragms available for compatibility

- UL and CSA hazardous approvals

- CRN approved

- RoHS Compliant

- NSF-61 Compliant

- Compact design

- Zero adjustable pointer

- Mirror-band dial and knife-edge pointer eliminates parallax error while assuring easy readability of precise measurements

- Teflon®-coated, stainless steel movement

- Integral span adjustment

- Wide selection of diaphragm and lower housing materials

- All welded construction

- Flushing port (type 403) provides easy cleaning / flushing due to process media prone to clogging

- Wetted parts compatible with many processes

- External pulsation adjustment to meet a variety of applications

- NEMA 7 & 9 explosion proof housing

- Dual chamber design allows for field calibration to be performed safely even with the power connected

- Wide selection of switch elements

- Stainless steel, Buna, Viton, Teflon and Monel diaphragms available for compatibility

- Adjustable setpoints from 15%-100% of range

- Fixed or adjustable deadbands

- UL and CSA hazardous approvals

- CRN approved

- RoHS Compliant

- NSF-61 Compliant

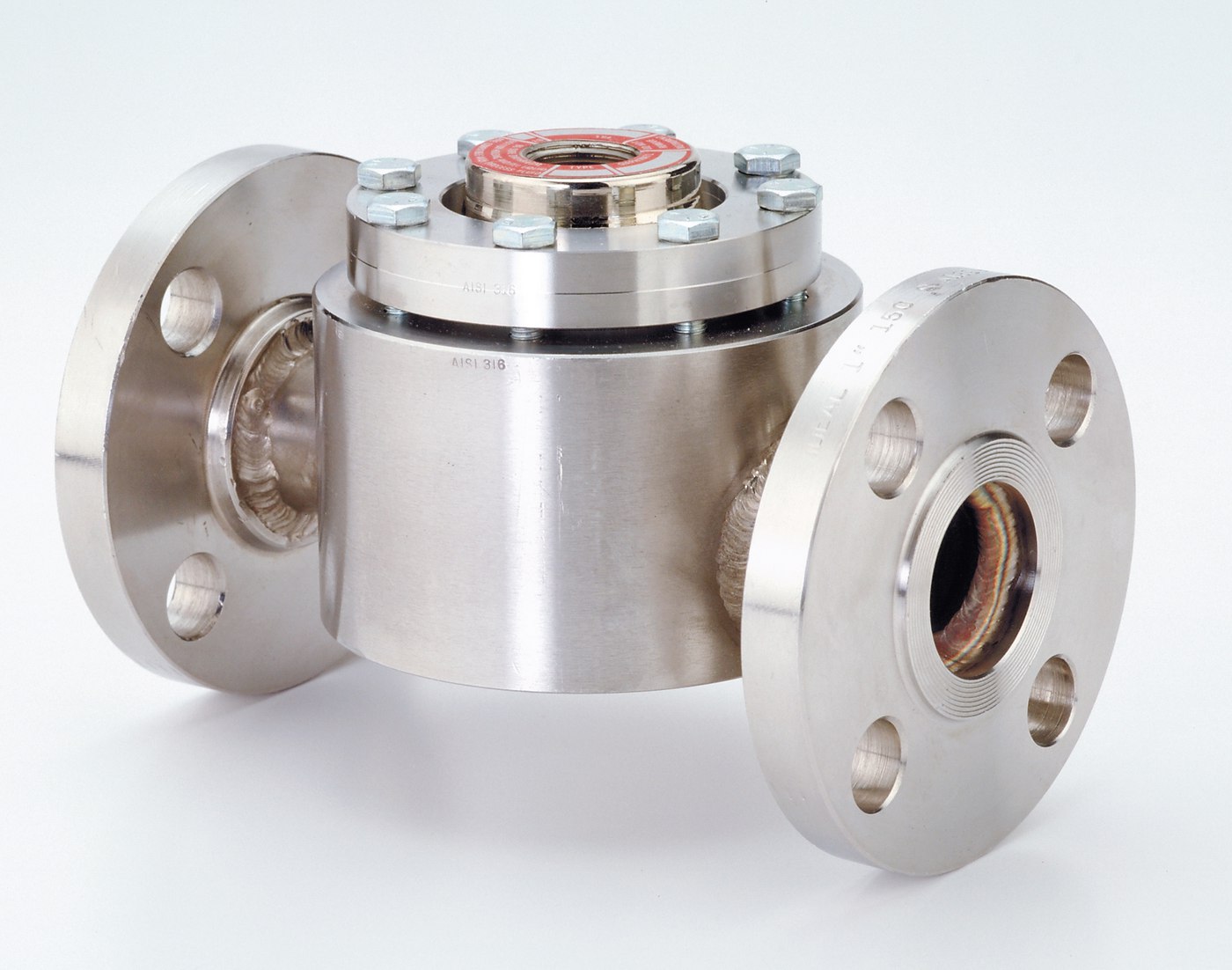

- Recommended where clamped joints are not acceptable

- All-welded construction; prevents inadvertent disassembly

- All-stainless steel construction; other materials available

- Flush port (type 501) provides easy cleaning / flushing for process media prone to clogging

- Clean or steam in place (CIP/SIP)

- 3 1/2″ dial size gauge with polysulfone window option can be autoclaved or sterilized

- Easy Zero™ provides external adjustability of instrument span (3½˝ dial)

- 12-20 RA (microinches) electropolished diaphragm surface

- Material certificates and certificate of conformance supplied as standard to EN 10204:2004 3.1

- True Zero™ reduces reading errors by using a “zero box” instead of conventional dial pins; this ensures gauge safety, integrity and system control

- PLUS!™ Performance (option)

- Autoclave or sterilize with polysulfone window

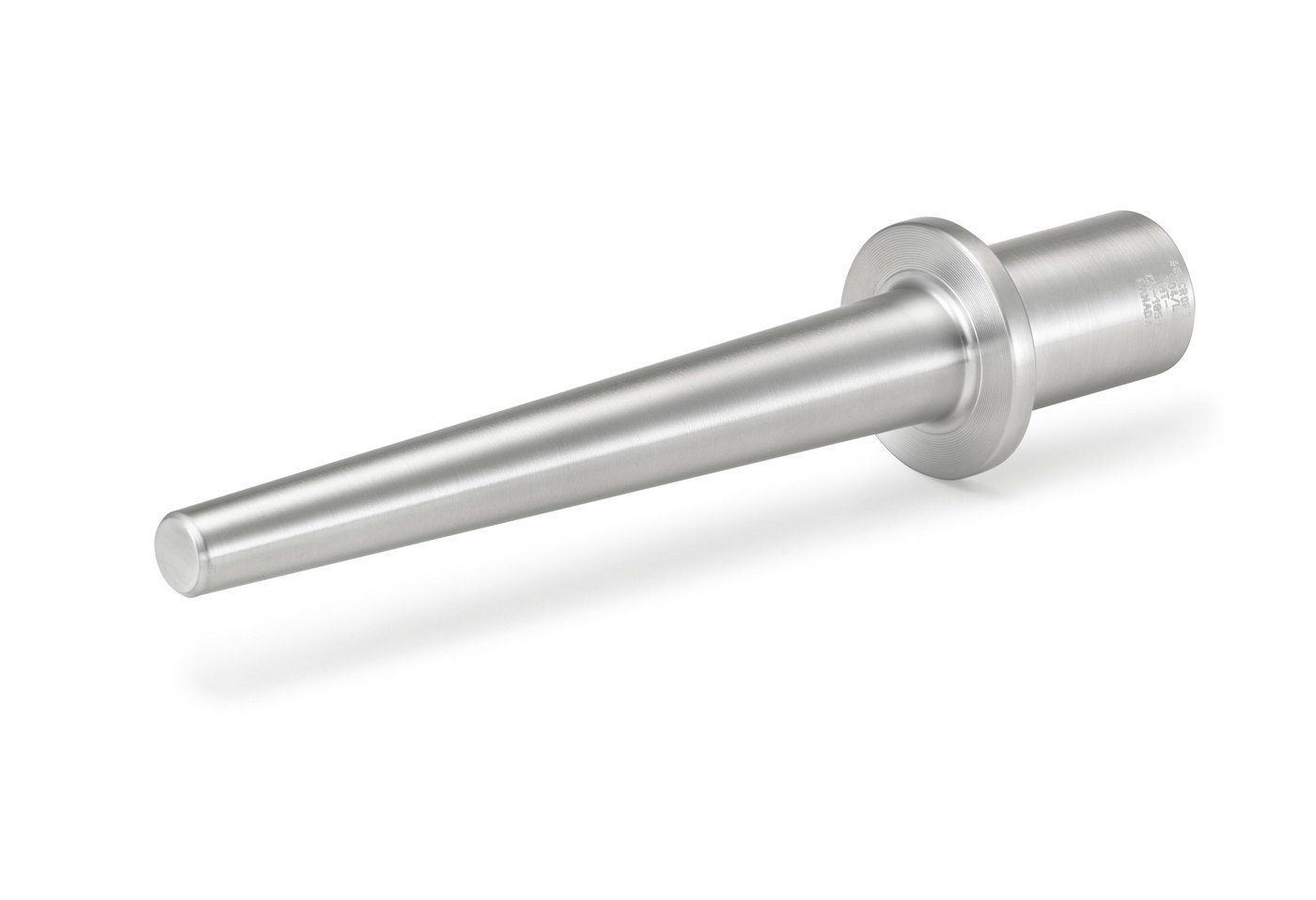

- One-piece bar stock construction

- Stamped with mil traceable materials and heat number

- Testing and certifications including Wake Frequency Calculations per ASME PTC 19.3 TW-2016

- Standard or customized shank dimensions and styles

- Wide selection of material

- Raised face, flat face and ring joint versions (ASME B16.5)

- One piece bar stock construction

- Full penetration welds on flanged thermowell

- Stamped with mil traceable material and heat number

- Testing and certifications including Wake Frequency Calculations per ASME PTC 19.3 TW-2016

- Standard or customized shank dimensions and styles

- Wide selection of material options

- One piece bar stock construction

- Stamped with mil traceable material and heat number

- Testing and certifications including Wake Frequency Calculations per ASME PTC 19.3 TW-2016

- Standard or customized shank dimensions and styles

- Wide selection of material options

- One piece bar stock construction

- Lap Joint Flanges availablility

- Stamped with mil traceable material and heat number

- Testing and certifications including Wake Frequency Calculations per ASME PTC 19.3 TW-2016

- Standard or customized shank dimensions and styles

- Wide selection of material options

- One piece bar stock construction

- Stamped with mil traceable material and heat number

- Testing and certifications including Wake Frequency Calculations per ASME PTC 19.3 TW-2016

- Standard or customized shank dimensions and styles

- Wide selection of material options

- One piece bar stock construction

- Stamped with mil traceable material and heat number

- Testing and certifications including Wake Frequency Calculations per ASME PTC 19.3 TW-2016

- Standard or customized shank dimensions and styles

- Wide selection of material options

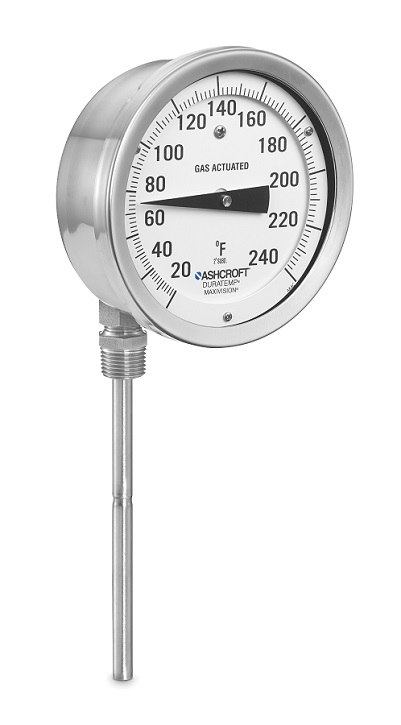

- Hermetically sealed case to prevent entry of moisture, interior corrosion and coil freeze-up

- External adjustment allows to be able to perform quick and limited span adjustments

- 3″ or 5″ Maxivision® dial for easy readability and parallax elimination

- Silicone dampened coil option for reduction of pointer flutter in high vibration applications and improved response times

- ±1% Accuracy to ASME B40.3

- Exclusive movementless design; eliminates wear and increases product life

- No head or elevation error due to bulb position

- Large 4.5″, 6″ or 8.5″ Maxivision® dial for easy readability and elimination of parallax

- Wide selection of temperature ranges, line lengths and bulb styles

- Various case and ring options for easy glass replacement or pointer adjustment

- ±1% Accuracy to ASME B40.3

- Exclusive movementless design; eliminates wear and prolongs product life

- Large 4.5″ Maxivision® dial for easy readability and elimination of parallax

- Display can be rotated 360-degrees for easy readability

- Wide selection of temperature ranges and stem lengths

- ±1% Accuracy to ASME B40.3

- Easily removable polycarbonate window for small zero adjustments

- FlutterGuard™ option to reduce movement wear and eliminate pointer flutter

- Case is suitable for intermittent or continuous services on natural gas

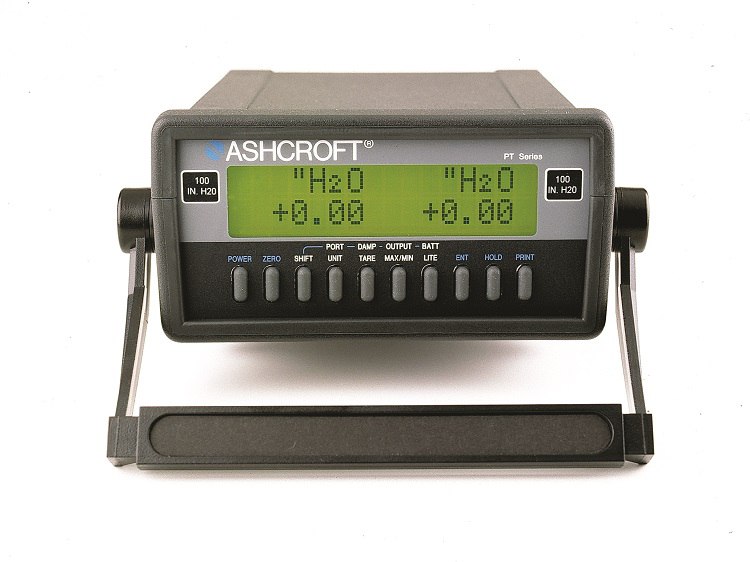

- Interchangeable pressure modules with ranges from 0.25 in. H2O up to 10,000 psi

- Large LCD display (1.5″ x 2.5″)

- FM, CSA and ATEX Intrinsically safe versions for Hazardous Locations (Options)

- Dual sensor module bay for interchangeable modules

- Data logging capability up to 16,000 records

- USB communications port SD memory card slot

- SD memory card slot

- Standard firmware features – min./max., tare, programmable damping, percent function, and switch test

Built in Power supply to power device under test

- Interchangeable pressure and temperature modules

- Digital interface compatability via RS232

- Dual sensor module bay and external input

- Many standard firmware features

- Choice units of measure

- Single or dual pressure measurement display

- Pressure modules are permanently installed

- Digital interface capability via RS232 interface

- Large LCD display

- Programmable damping, zero, engineering unit selection, tare and Min/Max memory

- Accuracy ±0.1% of reading NIST traceable primary pressure standard

- Includes complete set of weights for pressure generation

- Dual Range system includes Low and High pressure piston assemblies

- Portable, includes metal “tool box” for protection and portability

- Includes tools and adapters to accommodate most calibration requirements

- Accuracy ±0.1% of span

- 2-stage hydraulic pressure pump with integral shuttle valve

- Includes 6″ model A4A precision analog gauge with temperature compensation and NIST traceable calibration chart

- Single carrying case; contains pressure generation unit and up to 4 gauges

- Accuracy ±0.25% of span

- 2-stage hydraulic pressure pump with integral shuttle valve

- Includes 4 1/2″ 1082 test gauge (choice of 1 to 4 units) with temperature compensation and calibration chart

- Single carrying case; contains pressure generation unit and gauges

- Rugged design

- 1125A: 12 o’clock pointer position

- Electric contacts (optional)

- Available with diaphragm seals

- 12 o’clock pointer position

- Available with diaphragm seals

- Glass filled nylon case

- Easily removable window for wipe-down

- Direct mount or panel mount as standard

- High static pressure capability (up to 6,000 psi)

- Reed switches (optional) for direct system control

- Superior magnets for smoother pointer motion

- Glass filled nylon case

- Easily removable window for wipe-down

- Direct mount or panel mount as standard

- High static pressure capability of 3,000 psi

- Superior magnets for smoother pointer motion

- Reed switches (optional) for direct system control

- Glass filled nylon case

- Easily removable window for wipe down

- Direct mount or panel mount as standard

- High static pressure capability of 1,500 psi

- Superior magnets for smoother pointer motion

- Reed switches for direct system control (optional)

- Stainless steel case

- High static pressure capability (500 psi)

- Superior magnets for smoother pointer motion

- Reed switches (optional) for direct system control

- Glass filled nylon case

- Easily removable window for wipe-down

- Direct mount or panel mount as standard

- High static pressure capability of 500 psi

- Superior magnets for smoother pointer motion

- Reed switches (optional) for direct system control

- Static pressure capability up to 35 psi

- Superior magnets for smoother pointer motion

- Standard with in-line and back process ports

- Reed switches (optional) for direct system control

- Choice of temperature ranges (from -40° to 750°F)

- Multiple Switch options with SPDT or DPDT Switch configurations

- Fixed or limited adjustable deadband

- Direct or remote reading thermal systems

- Adjustable setpoints from 0%-100% of range

- Internal set point locking screw

- Wide selection of switch elements

- UL, CSA and CE approved

- SIL 3 Capable

- Choice of temperature ranges

- Adjustable setpoint from 0%-100% of range

- Fixed or limited adjustable deadband

- Direct or remote reading thermal systems

- Explosion-proof enclosure ensures uncompromising protection

- External locking screw (ATEX / IECEx approval only)

- Wide selection of switch element

- UL, CSA, ATEX and IECEx hazardous approvals

- CE approved

- SIL 3 Capable

- Fixed or adjustable deadbands

- Choice of temperature ranges (from -40° to 750°F)

- Direct or remote reading thermal systems

- Wide choice of switch elements

- Adjustable setpoints from 15%-100% of range

- Single or Dual adjustable set points

- UL, CSA and CE approved

- Choice of temperature ranges (from -40° to 750°F)

- Direct or remote reading thermal systems

- Wide selection of switch elements

- Adjustable setpoints from 15%-100% of range

- Fixed or adjustable deadbands

- Single or Dual adjustable set points

- UL, CSA and CE approved

- Adjustable setpoints from 15%-100% of range (-40 to 750°F)

- Fixed or adjustable deadbands

- Single or Dual adjustable set points

- Explosion-proof enclosure

- Dual chamber design, allows for safe field calibration of switch even with the power connected

- Direct or remote reading thermal systems

- Wide switch element selection

- UL and CSA hazardous approvals

- CE approved

- Compact design

- FlutterGuard™ option reduces movement wear and eliminates pointer flutter

- Heat Lot Traceable material certificates

- Electropolished diaphragm and housing

- Tri-Clamp® connections

- Pipe size; ½˝ to 2˝ mates with type 1036 Inline Sanitary Gauge

- Electropolished 316L SS wetted material, 12-20 RA internal surface finish

- Wide selection of Bourdon tube materials, pressure connections and pressure ranges

- Solid-front case design for safety

- Teflon®-coated, 400 stainless steel movement

- PLUS!™ Performance (option)

- Movementless system (coil)

- High shock capability

- External dial adjustment

- Low volumetric displacement – compatible with mini diaphragm seal

- Solid-front case design for safety

- Ranges from 15 psi to 100,000 psi

- PLUS!™ Performance (option)

- Rugged enclosure

- Choices of units of measure

- Integral transmitter

- PLUS!™ Performance (option)

- Inches of water ranges

- Bronze, 316 stainless steel or monel wetted parts

- Available with diaphragm seals

- Inches of water ranges

- Bronze, 316 stainless steel or monel wetted parts

- Available with diaphragm seals

- Utilizes a unique “dry cell” mechanism

- 316L stainless steel case welded to socket for system integrity

- Overload protection option up to 10 times F.S. range (optional)

- IP66 for use outdoor or in humid environments

- 316SS, Monel 400 or Hastelloy C-276 wetted parts

- Custom dials available

- Orange or yellow case for quick identification (optional)

- Fill fluid for oxidizing acids

- Pressure ranges up to 10,000 psi

- Silicone-free PLUS!™ Performance (optional)

- Cleaning for oxygen service (optional)

- NACE compliant assemblies

- Depths to 2,500 meters

- 100% Liquid Filled (Glycerin)

- Compensated Case

- Bayonet Lock Ring

- 316L stainless steel case and wetted material

- Corrosion resistant construction

- Depths to 6,000 meters

- Rugged construction for extreme undersea environments

- Solid drilled, bar stock cases

- 316L stainless steel wetted material and case

- Corrosion resistant construction

- Stainless steel, bronze and monel Bourdon tube options

- Wide selection of pressure connections and pressure ranges

- Teflon®-coated, 400 stainless steel movement

- PLUS!™ Performance (option)

- Wide selection of Bourdon tube materials, pressure connections and pressure ranges

- Solid-front case design for safety

- Epoxy-coated system offers superior corrosion resistance

- PLUS!™ Performance (option)

- Compact case

- Specialized instrument for pump, turbine and compressor service

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- True Zero™ reduces reading errors by using a “zero zone” instead of conventional dial pins (posts); this ensures product safety, integrity and system control

- Corrosion resistant ABS case

- Underwriters Laboratory listed and Factory Mutual approved

- Single scale, dual scale and triple scale dials available

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- FlutterGuard™ eliminates pointer flutter for optimum readability

- Easy access window allows for minor span adjustments

- 1007P ABS case offers durability and corrosion resistance

- 1001T gauges are tested to detect leaks as small as 2.8 x 10 -4 cc per second

- Corrosion-resistant case

- Adjustable pointer

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- True Zero™ reduces reading errors by using a “zero zone” instead of conventional dial pins (posts); this ensures product safety, integrity and system control

- FlutterGuard™ (option) reduces movement wear and eliminates pointer flutter; extends product life and allows easy gauge readability

- Accuracy 0.1% of span

- Gauge, Compound and Vacuum ranges

- Pressure ranges 15 to 100,000 psi

- Mirror-band dial and knife-edge pointer eliminates paralax error while

assuring easy readability of precise measurements - Solid-front case design and blow-out safety back protect users from

extreme overpressure - Optional Slotted link – protects gauge from sudden decrease in pressure

- Optional Thermal Compensation – to maintain accuracy over a wide

temperature range from -25° to +125°F

- Available with a wide variety of instruments, orientations and configurations to suit most processes

- These transmitters and multi-instrument configurations can be respanned and are calibrated together as an assembly to ensure accurate pressure measurement.

- Mechanical rotation is directly proportional to volume change due to piston travel

- Integral balance valve equalizes pressure and acts as pressure-relief valve

precision pressure adjustment between vacuum and 3,000 psi - Does not require compressed gas source to generate low pressure less than 1 psi.

- Convert from vacuum to pressure

by simply twisting a knob. - Large volume fine adjustment piston allows precise pressure control.

- Precicely vent pressure with soft seat bleed valve.

- Soft sealed bleed valve allows for precisely controlled pressure relief

- Two outlets ports with quick test adapters installed in the pump body

- Two outlet ports with quick test adapters installed in pump body.

- Pressue media fluid must be compatiable with wetted parts that are made from Buna-N, Teflon, polysulfone, brass, aluminum and stainless steel

- Visual pressure indicator

- Clean or Steam in Place (CIP/SIP) pressure sensor

- Remote mount sensor (optional)

- 10 engineering units

- Password protection

- Damping

- Display update rate

- Min/Max

- Auto-off timers

- Field recalibration option

- Non-adjustable red and black pointers

- Two independent systems and movements; bronze Bourdon tubes

- Non-adjustable red and black pointers

- Two independent systems and movements; bronze Bourdon tubes

- Integral handle allows easy station-to-station transport

- Pressure ranges from 30 psi to 20,000 psi

- +/- 0.25% of span static accuracy (BFSL) at reference temprature

- All stainless steel wetted material

- Highly configurable; wide selection of pressure connections and electrical terminations

- Voltage and 4-20mA output options

- High EMI/RFI immunity rating

- UL/cUL and CE approved

- RoHS compliant

- NSF-61 Compliant

- Pressure ranges from 5 to 5000 psig, 15 to 500 psia

- +/- 0.50% of span static accuracy (BFSL) at reference temperature

- All 316L Stainless Steel wetted materials

- All-welded sensor and pressure connections

- Highly configurable; wide selection of pressure connections and electrical terminations

- Voltage and 4-20mA output options

- High EMI/RFI immunity rating

- UL/cUL and CE approved

- RoHS compliant

- NSF-61 Compliant

- Pressure ranges from 30,000 to 72,000 psi

- +/- 1.0% of span accuracy

- Titanium sensor and pressure connection

- A choice of pressure connections geared specifically for high pressure installations

- Voltage and 4-20mA output options

- Ingress Protection: up to IP67 (IP69K option)

- CE approved

- Pressure ranges from vacuum to 20,000 psi

- +/-0.50% or +/- 1.0% of span accuracy

- Millivolt outputs

- NEMA 4X ingress protection

- All stainless steel wetted materials

- Highly configurable – broad selection of pressure ranges, output signals, pressure connections and electrical

- terminations

- CRN approved

- Pressure ranges from 45 to 20,000 psi

- +/-0.50% or +/- 1.0% of span accuracy

- Millivolt output

- NEMA 4X

- All stainless steel wetted materials

- 304 stainless steel housing (optional)

- Compact and lightweight design

- CRN approved

- Pressure ranges from 60 psi to 5,000 psi

- +/- 1.0% of span accuracy

- All Stainless steel design with flush-mounted integral 316 Stainless steel diaphragm

- Voltage and 4-20mA output options

- PMC adapter

- NEMA 4X Housing

- Pressure ranges from 30 to 1,000 psi

- ±1.00% of span accuracy

- All 316 stainless steel welded design

- Electropolished 316 SS diaphragm

- 1.5″ and 2.0″ Tri-Clamp™ process connection

- Voltage and 4-20mA output options

- Broad selection of pressure connections and electrical terminations

- 3A sanitary approved

- Pressure ranges from vacuum to 7,500 psi

- +/- 0.50% or +/- 1.0% of span accuracy

- All-welded sensor and pressure connection

- Highly configurable; wide selection of pressure connections and electrical terminations

- Voltage outputs

- High EMI/RFI immunity rating

- CE approved

- RoHS compliant

- All-welded stainless steel construction

- Pressure ranges from vac to 20,000 psig, 15 to 500 psia

- +/- 0.25% or +/- 0.50% of span accuracy

- Voltage and 4-20mA output options

- High EMI/RFI protection

Ingress Protection: up to IP67 (IP69K OPT.) - Wide selection of process and electrical connections

- CE approved

- RoHS compliant

- All-welded sensor and pressure connection

- Ranges from 500 to 7,500 psi

- +/- 0.25% of span accuracy

- Highly configurable; wide selection of pressure connections and electrical terminations

- Voltage and 4-20mA output options

- Field proven polysilcone thin film pressure sensors

- Custom designs to withstand high voltage available

- Tested to 26 g random vibration

- UL approved

- CANbus interface output via CANopen® or SAE J1939 protocol

- Ranges from 5 to 20,000 psi

- +/- 0.25% or +/- 0.50% of span accuracy

- Selection of pressure and electrical connection options suited to meet CANbus applications

- Rugged construction with stainless steel housing and wetted materials

- Customizable communication protocols available

- CE approved

- RoHS compliant

- Field selectable units of measure

- Large, field-adjustable 4-digit LCD display

- Adjustable display response time

- Excellent overpressure protection

- Ranges available down to 0.1 in. H2O

- CE Mark standard

- Wide selection of output signals and differential pressure ranges down to +/- 0.05 in. H2O

- Board level OEM versions available

- Excellent overpressure protection.

- Custom pressure range calibrations are readily available.

- 3-Year Warranty

- CE Mark optional

- TruAccuracy™ performance ensures the XLdp meets its rated accuracy out of the box and is ready for installation with no additional calibration adjustments required.

- Wide selection of differential pressure ranges down to +/- 0.05 in. H2O

- Easy installation

- Excellent overpressure protection

- Custom pressure range calibrations are readily available

- Superior long-term stability

- 3-Year Warranty

- CE Mark optional

- TruAccuracy™ performance ensures the IXLdp meets its rated accuracy out of the box and is ready for installation with no additional calibration adjustments required.

- Rugged enclosure

- Wide selection of output signals and differential pressure ranges down to +/- 0.05 in. H2O

- Integral electrical termination isolates electronics from the process connections

- Optional FM approval for hazardous locations

- Outstanding overpressure protection

- Wide operating temperature capability

- Superior long-term stability

- 3-Year Warranty

- FM Approval optional

- UL94-V0 rated PBT case

- Calibrated ratiometric output

- Low voltage power requirement

- Through holes allow for easy mounting to PC boards

- Ranges available down to +/- 0.1 in. H2O

- Compact design

- Good overpressure protection

- CE Mark standard

- Rugged 304 stainless steel housing

- Uses Ashcroft’s proven thin film technology

- +/-0.25%, +/- 0.50% or +/-1.0% of span accuracy available

- Highly configurable with a wide selection of pressure connections and electrical terminations

- Pressure ranges from vacuum to 10,000 psi and 0 to 7,500 psia

- Multiple voltage or 4-20mA outputs available

- Externally adjustable zero and span access (optional)

- CE and CRN approved

- RoHS compliant

- Uses Ashcroft’s proven thin film technology

- Rugged 304 stainless steel housing

- +/-0.25%, +/- 0.50% or +/-1.0% of span accuracy available

- Highly configurable with a wide selection of pressure connections and electrical terminations

- Pressure ranges from vacuum to 10,000 psi and 0 to 7,500 psia

- 4-20 mA output

- Optional zero and span access

- FM and CSA intrinsically safe/non-incendive approved

- CE approved

- RoHS compliant

- Compact, robust design

- ±25% of span accuracy for most ranges

- Pressure ranges: Gauge 50 to 7,500 psig, Compound ranges to -15 to 50 psig

- Min./max. feature records low and high pressure events

- Analog scaling

- “Loop check” allows easy display of user-defined units and verification without applying pressure

- Bright backlit 4-digit LCD display

- Easily rotatable display, 90° increments

- CRN and CE approved, RoHS compliant

- Compact, robust design

- +/- 0.5% of span accuracy

- Ranges from 4 to 400 in. H2O (Differential and Bi-Directional)

- Min./max. feature records low and high pressure events

- Analog scaling

- Simple internal “push button” configurability

- Flow measurement/square root extraction where the momentary flow rate can be displayed and analog signal can be output

- “Loop check” allows easy display of user-defined units and verification without applying pressure

- Bright backlit 4-digit LCD display

- CE approved

- RoHS compliant

- Ultra-stable CVD Sensing Technology

- Ranges from vacuum to 150 psi

- 4-20mA or 1-5Vdc output

- 1.25″ c-seal or w-seal configuration

- Low internal volume (<0.9cm3)

- 7RA (0.18µm) internal surface finish

- Excellent EMI/RFI resistance

- Class 100 clean room cleanroom packaged and double bagged

- CE and UKCA approval

- RoHS compliant

- Easy user-programmable buttons

- Large LED display

- Field Selectable Outputs: Current and Voltage

- Enhanced product capability with optional communication adapters, relays and expansion modules

- Glass filled nylon case

- Easily removable window for wipe-down

- Direct mount or panel mount as standard

- High static pressure capability (up to 1,000 psi)

- Reed switches (optional) for direct system control

- Superior magnets for smoother pointer motion

- Wide selection of outputs

- Custom lengths

- Custom process connections

- Custom electrical connections (cable or connectors)

- RTDs sensor elements

- All-stainless steel construction

- Direct or remote mount versions

- Wide selection of temperature ranges

- Dry or liquid filled

- IP65 protection

- EN 13190

- PTFE/PFA wetted parts

- Low metal ion elution

- Compatible with pipe diameters from 0.25 to 1.0 in. O.D.

- Capacitance sensor for excellent thermal stability

- Multiple mounting options include tube connections, press fit nuts, flared nuts and threaded nuts

- Class 100,000 cleanroom packaged and bagged

- Designed for low and negative pressure measurement

- IP65 ingress rating

- PTFE/PFA wetted parts

- Corrosion resistant to chemicals such as hydrofluoric acid

- Low metal ion elution

- Compatible with pipe diameters from 0.25 to 0.5 in. O.D.

- Capacitance sensor for excellent thermal stability

- Multiple mounting options include tube connections, press fit nuts, flared nuts and threaded nuts

- Class 100,000 cleanroom packaged and bagged

- Designed for DIN 43772 thermowells

- Manufactured to IEC 60751

- Custom Lag Extensions

- Available with and without transmitters

- Mineral Insulated Inset

- Intrinsically Safe and Non-Incendive designs available

- Available with DIN mounting plate or spring loaded fitting designs

- Designed for ISA-ds 49 style thermowells

- Manufactured to IEC 60751

- Custom Lag Extensions

- Available with and without transmitters

- Mineral Insulated Inset

- Intrinsically Safe designs available

- Explosion Proof designs available

- Designed for DIN 43772 thermowells

- Manufactured to 60584-2, or ANSI MC 96.1

- Available with and without transmitters

- Intrinsically Safe designs available

- Available with DIN mounting plate or spring loaded fitting designs

- Designed to be used with ISA-ds 49 style thermowells

- Manufactured to 60584-2 or ANSI MC 96.1

- Available with and without transmitters

- Intrinsically Safe designs available

- Explosion Proof designs available

- Weldable sensor head

- Available with and without transmitters

- Integrated expansion loop allows for expansion and contraction within temperature changes

- Intrinsically Safe and Non-Incendive designs available

- Explosion Proof designs available

- For mounting in thermowells

- Manufactured to IEC 60751

- Available with and without transmitters

- Mineral Insulated Insert

- Intrinsically Safe designs available

- For mounting in thermowells

- Manufactured to 60584-2, or ANSI MC 96.1

- Available with and without transmitters

- Intrinsically Safe designs available

- Available with remote heads and flex armor

- Flexible configurations with other without lead wires and connectors

- Heavy duty MgO cable

- Intrinsically Safe and Non-Incendive designs available

- Available with remote heads and flex armor

- Flexible configurations with or without lead wires and connectors.

- Heavy duty MgO cable

- Intrinsically Safe and Non-Incendive designs available

- Multi-thermowell flanged assemblies with guide tube and compression devices

- Straight multipoint for reactors with spring-loaded thermal blocks or welded heat transfer blocks

- Flexible multipoint for reactors with mineral insulation cables with standard, reinforced or double wall

- MultiOne thermocouples for reactors offer multiple sensing points along the length of MI-cable at various predetermined locations inside the catalyst bed

- Multipoint accessories for reactors, such as: metal brackets, wall-mounting devices and soldering clip sources of thermal dissipation.

- PTFE/PFA wetted parts

- Corrosion resistant to chemicals such as hydrofluoric acid

- 4 digit LED display with NPN switch outputs

- Compatible with pipe diameters from 0.25 to 0.5 in. O.D.

- Capacitance sensor for excellent thermal stability

- Multiple mounting options include tube connections, press fit nuts, flared nuts and threaded nuts

- Class 100,000 cleanroom packaged and bagged

- ATEX and IECEx Type EX ec (increased safety) approval

- Ultra-stable CVD Sensing Technology

- Available in gauge and compound ranges

- Low internal volume (<0.9cm3)

- 20RA (0.50μm) or optional 7RA (0.18μm)

- Excellent EMI/RFI resistance

- Class 100 clean room packaged and double bagged

- CE and UKCA approved

- RoHS compliant

- Ultra-stable CVD sensing technology

- Available in gauge and compound ranges

- 4-20mA output

- Low internal volume (0.9cm3)

- 20RA (0.5μm) or optional 7RA (0.18μm)

- Excellent EMI/RFI resistance

- Class 100 cleanroom packaged and double bagged

- CE and UKCA approved

- RoHS compliant

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- True Zero™ reduces reading errors by using a “zero box” instead of conventional dial pins (posts);this ensures product safety, integrity and system control

- FlutterGuard™ (option) reduces movement wear and eliminates pointer flutter; extends product life and allows easy gauge readability

- Rugged design

- Available with diaphragm seals

- Choice materials

- Select field-adjustment dampening for meeting requirements

- Horizontal or vertical installation

- Self-cleaning action

- Compact size and lightweight

- All-welded connections

- Compatible with Tri-Clover® and Cherry Burrell® S line

- Hermetically sealed case to prevent entry of moisture, interior corrosion and coil freeze-up

- External adjustment allows to be able to perform quick and limited span adjustments

- 3″ or 5″ Maxivision® dial for easy readability and parallax elimination

- Silicone liquid fill for reduction of pointer flutter in high vibration applications and improved response times

- ±1% Accuracy to ASME B40.3

- Hermetically sealed, tamper-proof case to prevent entry of moisture, interior corrosion and coil freeze up

- 2″, 3″ or 5″ Maxivision® dial options for easy readability and parallax elimination

- Silicone dampened coil for reduction of pointer flutter on high vibration application and provides improved response times

- ±1% Accuracy to ASME B40.3

- Adjustable throttling device

- Choice of material: Carbon steel (7001L) or 316 stainless steel (7004L)

- Rated up to 10,000 psi (7001L) and 7,000 psi (7004L)

- Digital Indicating Display

- Ranges up to 20,000 psi

- Easy to program setpoint and deadband

- Incorporates thin film sensor technology which provides repeatability and durability

- Multi-turn potentiometers allows easy setpoint and deadband adjustments Switch

- Relay status indication light

- SPDT 10 amp relay with optional 4-20mA output

- Designed for high cycle life ≥ 10 million cycles

- CRN approved

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm welded (metallic) or bonded (elastomer) to top housing

- All-stainless steel movement

- Overpressure protection up to 10 times full scale (option)

- Socket welded to the case

- Allows for easy alignment of measuring instruments

- 316L Stainless steel construction

- Good for pressures to 10,000 psi

- Pressure ranges up to 20,000 psi

- Incorporates Ashcroft’s thin film sensing technology which provides repeatability and durability

- Multi-turn potentiometers allow easy setpoint and deadband adjustments

- Relay switch status indication light

- SPDT 10 amp relay with optional 4-20 mA output

- Designed for high cycle life ≥ 10 million cycles

- CRN approved

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm threaded to top housing

- 316L stainless steel case and wetted parts

- External zero adjustment

- Flow measurement dial (optional)

- Electric contacts (optional) for process monitoring and control

- Explosion-proof enclosure with hermetically sealed switch elements provide added safety and reliability

- Wide selection of switch elements

- Multiple process connections available

- Adjustable setpoints from 15%-100% of range with fixed deadband

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm welded (metallic) or bonded (elastomer) to top housing

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm threaded to top housing

- Stainless steel case

- High static pressure capability (up to 3,000 psi)

- Superior magnets for smoother pointer motion

- Reed switches (optional) for direct system control

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm welded (metallic) or bonded (elastomer) to top housing

- Helical strake design

- Stable pressure field

- One piece bar stock construction on shank

- No need for velocity collars

- CFD (Computational Fluid Dynamic) analysis provided for challenging applications

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm (elastomer) clamped between top and bottom housings

- Flush port (type 303) provides easy cleaning / flushing due to process media prone to clogging

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm threaded to top housing

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm threaded to top housing

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm threaded to top housing

- Ultra-compact design

- 3-in-1 capability: digital pressure gauge, switch and transducer

- Differential pressure and compound ranges from 0.25″ to 25.0″ water column in. H2O

- +/- 1.5% of span accuracy

- 1-5 Vdc with (2) PNP or NPN switch outputs

- Min. / max. feature records low and high pressure events

- Programmable switch setting and analog scaling

- Simple “push button” operation

- Combination of digital pressure gauge, switch and transducer

- Numerous standard ranges available

- CE approved

- RoHS compliant

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm welded (metallic) or bonded (elastomer) to top housing

- Ultra-compact design

- +/- 1.0% of span accuracy

- 3-in-1 capability: digital pressure gauge, switch and transducer

- 1-5Vdc with PNP or NPN switch outputs

- Min. / max. feature records low and high pressure events

- Programmable switch setting and analog scaling

- Simple “push button” operation

- Combination of digital pressure gauge, switch and transducer

- Pressure ranges: Gauge 50 to 1,500 psig, Compound -15 to 75 psig through -15 to 300 psig

- CE approved

- RoHS compliant

- 316L stainless steel top housing (standard)

- Wide selection of diaphragm and lower housing materials

- Diaphragm welded (metallic) or bonded (elastomer) to top housing

- Compact footprint

- Indicating transducer with analog scaling and switch outputs.

- 4-20mA with (1) NPN or PNP switch output or (2) NPN or PNP switch outputs

- +/- 1.0% of span accuracy

- Programmable switch setting and analog scaling

- Min. / max. feature records low and high pressure events

- Simple “push button” operation

- GloBand™ display provides 360-degree visibility

- Pressure ranges: Gauge 50 to 7,500 psig, Compound -15 to 75 psig through -15 to 300 psig

- All stainless steel wetted materials

- Rugged aluminum housing

- CE approved

- RoHS compliant

- Field-adjustable; settings and circuit

- Select contact arrangements

- Robust, cast-aluminum enclosure

- 3-in-1 capability: digital pressure gauge, switch and transducer

- +/- 0.5% of span accuracy

- Differential pressure ranges from 75 to 300 psid

- 4-20mA or 1-5 Vdc output

- Min. / max. feature records low and high pressure events

- Programmable switch setting and analog scaling

- Bright LED display; pressure and switch status

- Internal “push button” settings allow for field selection between the DP value and the line pressure readings from either sensor

- External “push-button” allows user to display P1, P2 or DP without opening cover

- All stainless steel wetted parts

- CRN approved

- Transmission distance: 1000 feet

- PowerFlex™ movement provides superior resistance to shock, vibration and pulsation; extends product life and reduces maintenance costs

- True Zero™ reduces reading errors by using a “zero zone” instead of conventional dial pins (posts); this ensures product safety, integrity and system control

- FlutterGuard™ (option) reduces movement wear and eliminates pointer flutter; extends product life and allows easy gauge readability

- Stainless steel movement with Teflon®-coated pinion and shaft

Accuracy |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Case Material |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|